Welcome to B&D Inspection systems

Welcome to B&D Inspection systems

B&D Inspection Systems is a joint venture between BOF NDT and DITS Pty Ltd, two of Australia’s most respected inspection service providers. With a combined legacy spanning over three decades, B&D unites deep technical expertise, regional strength, and an unwavering commitment to innovation.

Headquartered in the Northern Territory and Western Australia, we are strategically positioned to service the mining industry across WA and NT, delivering tailored inspection solutions with the speed, precision, and reliability our clients demand.

Our core focus is on fixed plant and mobile plant inspection systems, ensuring compliance with OEM and industry standards while driving safety, reliability, and efficiency. Leveraging our advanced digital platform, inspections are carried out via tablet-based checklists, with results automatically converted into reports and accessible dashboards. Clients benefit from real-time insights and risk-based prioritization, enabling smarter maintenance planning and reduced downtime.

With innovation at the core of our business, we provide our clients with not only inspection compliance but also the ability to make smarter, faster, and safer operational decisions.

SERVICES

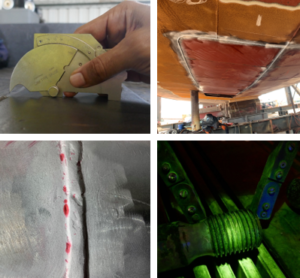

NDT Surface Methods

Visual Inspection, Magnetic Particle & Dye Penetrant testing.

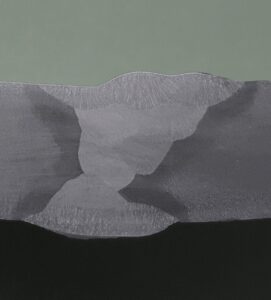

NDT Radiography

We offer a full range of gamma, X-ray & digital radiography testing services with a radiation bay in our local premises & the ability to do onsite radiography with a mobile darkroom for remote pipeline work.

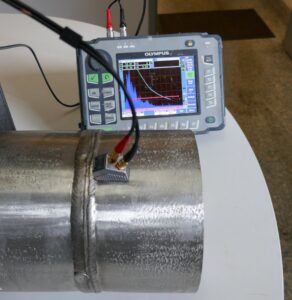

NDT Ultrasonic

NDT Phased Array

NDT Eddy Current

Eddy Current Inspection to identify flaws through paint or coatings.

Weld Procedures

Development of new welding procedures, review of existing welding procedures & recommend repair procedures.

Welder Qualifications

B&D offers welder qualifications to an extensive range of codes. This includes all your visual inspection, macro examination & radiography needs.

Coating Inspection

B&D has NACE Level 2 & 3 Coatings inspectors, as well as a full range of Coating Inspection Test methods to meet your needs.

Vessel and Piping Inspection

AICIP & API Inspectors for Internal & External Inspection of Pressure Vessels & Piping.

API 653 Tank Inspection

API 653 inspection using the latest Tecnology in Tank floor scanning and Corrosion mapping

Pressure Relieving Device Testing

ASME PRD Inspection & Maintenance Certified Technicians for the Inspection, Testing, Maintenance & Certification of Pressure Relieving Devices.

Pressure Gauge Testing

Inspection, Testing & Certification of In-Service Pressure Gauges.

Hydrostatic Testing

Hydrostatic Testing of Pressure Equipment to Pressures up to 20,000 PSI (138,000kPa) .

Heat Treatment

Heat Treatment Onsite using flexi cermamic pads or in our workshop Kiln to temperatures up to 1200°C Programable to your requirements.

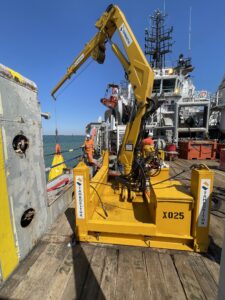

Load Testing

Load Testing using our pad eye tester to loads up to 20 ton, aswell as witnessing and reporting load testing to clients specifications.

Rope Access

Experienced IRATA Certified Rope Access Technicians.